roller grinding mill on sale China quality roller grinding mill

Quality roller grinding mill on sale you can find roller grinding mill from the most reliable suppliers on We find 600 products about roller grinding mill from 136 manufacturers suppliers Polysius Roller Mills For grindingPolysius Roller Mills For grindingYGM130 High Pressure Overhang Roller Mill Features: pared with other grinding mill, the output can increase 1020% under the same condition YGM130 High Pressure Overhang Roller Mill Working Principle: When it is put into use, the materials to be grinded are put into the main frame through the feedin bin on the side coverpowder grinding roller mill, powder grinding roller Vertical Roller Mill for Clinker Grinding 1 First Principles of Grinding Ball mills and vertical mills use different forces to achieve the necessary size reduction of clinker and gypsum plus other materials – such as pozzolan, flyash, limestone and slag – Vertical Roller Mill for Clinker GrindingVertical Grinding Mills GKLM series vertical grinding mill is one advanced powder making mill through our engineer research and experience and bringing in advanced technology of the world It is ideal equipment for superfine milling industry which integrated with crushing, drying, grinding and collectingVertical Grinding Mill, Vertical Roller Mill Powder

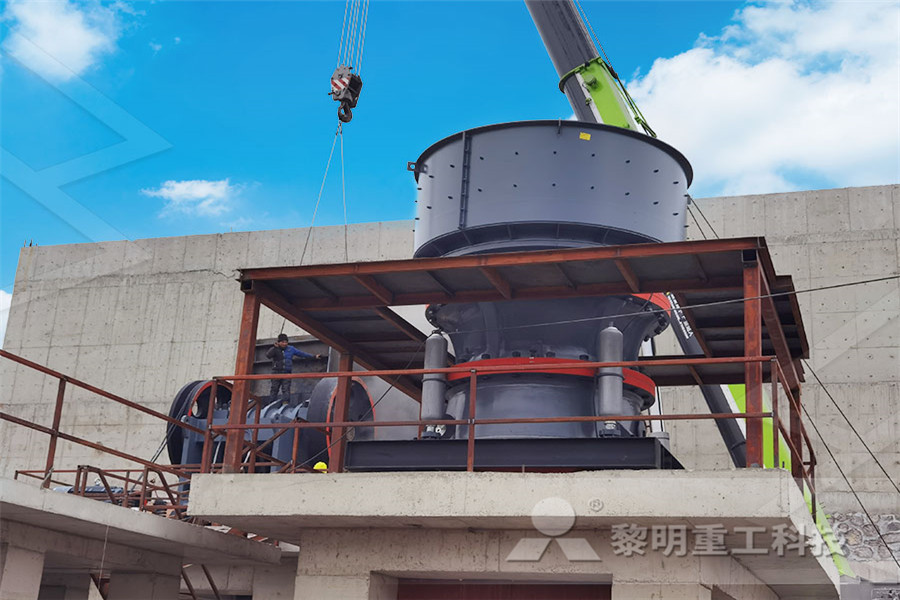

Industrial Roller Mill Roller Mill Manufacturer

The feeder (A) introduces raw material into the grinding chamber in the base of the Roller Mill (B) at a rate determined by pressure variations with the grinding mill Plows located ahead of each roller direct the material upward and between the grinding rolls and the heavy alloy Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill systemCement grinding Vertical roller mills versus ball mills The roller mill appears to be a more energy efficient method of grinding grain than the hammer mill Reece et al (1985) found that the roller mill required 145% less energy for grinding than the hammer mill, but the particle size characteristics of the processed grain were greatly differentHammer Mill Versus Roller Mill Grinding of Corn for Alibaba offers 2,755 4 roller grinding mill products A wide variety of 4 roller grinding mill options are available to you, such as local service location, applicable industries, and warranty4 roller grinding mill, 4 roller grinding mill Suppliers 4,943 powder grinding roller mill products are offered for sale by suppliers on Alibaba, of which mine mill accounts for 43%, abrasive tools accounts for 1%, and material handling equipment parts accounts for 1% A wide variety of powder grinding roller mill options are available to you, such as south africa, germany, and mexicopowder grinding roller mill, powder grinding roller

Roller mill, Roller grinding mill All industrial

roller grinding mill minerals processing industry are gaining increasing attention Since its introduction in 1985, high pressure comminution with roller presses (also known as HPGR) has been proving its significance in energy efficient crushing Compare this product Remove from comparison toolHC1700 Grinding Mill HC1700 Grinding Mill is a newly developed largescale roller mill by Guilin Hongcheng The equipment referenced the operating principle of pendulum mill and improved the swinging method Without changing other parameter, the centrifugal grinding HC1700 Grinding Mill, Raymond Roller Mill, Pendulum The advantages of the vertical roller mill include a high level of grinding efficiency combined with reduced energy consumption For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product Vertical roller mills offer supreme grinding NETZSCH ECUTEC's Altai Pendular Roller Mills combine high classifying efficiency with the advantages of a multipurpose mill Drying, grinding and classifying can be done in open or closed systems Finenesses down to 45 µm can be achieved in just one stepAltai Pendular Roller Mill NETZSCH Grinding Grinding bed thickness Grinding Speed, Time of Roller Passage The time of action of the grinding pressure k z P 2 k = ( kg sec/ m ) v a where : z = number of rollers () p = total contact force (kg) v = angular velocity rolling circle radius (m/second) a = effective width of rollers (m) Regular Planned Mill MaintenanceRoller Mill Mill (Grinding) Wear

Ball Mill Roller Press Systems for Cement Grinding

Roller Press with Ball Mill Cement Grinding Systems Selection Principle As a professional contractor of cement plant, in the design process of cement plant, our team will select the most appropriate cement grinding system after fully considering the production condition and discussing with the client The roller mill appears to be a more energy efficient method of grinding grain than the hammer mill Reece et al (1985) found that the roller mill required 145% less energy for grinding than the hammer mill, but the particle size characteristics of the processed grain were greatly differentHammer Mill Versus Roller Mill Grinding of Corn for AWM Table Roller Mill The product is subjected to compressive stress between the grinding table and the grinding rollers The specific grinding force (contact force divided by the crosssectional area of the grinding roller) is in the range between approx 05 and 1 N/mm², whereby the effective pressures in the material bed are naturally much higherAWM Table Roller Mill Hosokawa Micron Ltd KTV can provide you with quality roller mill grinding equipment benefitting from the latest technological advances This technology is designed to produce uniform particle sizes with a minimal generation of "fines" for thousands of applications where particle size reduction is requiredKTV Inc Roller MillGrinding roller is core part of vertical mill SYMMEN METAL Casting can provide customized service according to customers' different processing requirements Besides, it provides finished product manufacturing service for grinding roller including casting, finished machining, surfacing welding, etc We gained good reputation from customersGrinding Roller Manufacturer From China Symmen

roller mill for grinding pentataalnl

Grinding roller for vertical mill The grinding roller is the vital grinding component of vertical mill Because the grinding roller can directly exert force on the material, the grinding roller has high requirements for hardness and wear resistance in actual productionThe CHAENG grinding rollers have the characteristics of high hardness, good crack resistance, good abrasion resistance and MTM130X Ultrafine Mill Based on many years research, our mill experts designed MTM130X Series strengthened Ultra fine mill on the basis of our original patented product LUM Series Vertical Roller Mill Base on ZENITH abundant experience in producing vertical grinding mill and the latest technology from Taiwan Germany, developed the Vertical roller mill,grinding mill for saleThe advantages of the vertical roller mill include a high level of grinding efficiency combined with reduced energy consumption For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product Vertical roller mills offer supreme grinding AWM Table Roller Mill The product is subjected to compressive stress between the grinding table and the grinding rollers The specific grinding force (contact force divided by the crosssectional area of the grinding roller) is in the range between approx 05 and 1 N/mm², whereby the effective pressures in the material bed are naturally much higherAWM Table Roller Mill Hosokawa Micron Ltd Grinding bed thickness Grinding Speed, Time of Roller Passage The time of action of the grinding pressure k z P 2 k = ( kg sec/ m ) v a where : z = number of rollers () p = total contact force (kg) v = angular velocity rolling circle radius (m/second) a = effective width of rollers (m) Regular Planned Mill MaintenanceRoller Mill Mill (Grinding) Wear

Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it comes to performing several process steps in one unit The roller mill appears to be a more energy efficient method of grinding grain than the hammer mill Reece et al (1985) found that the roller mill required 145% less energy for grinding than the hammer mill, but the particle size characteristics of the processed grain were greatly differentHammer Mill Versus Roller Mill Grinding of Corn for Taking grinding P o425 cement as an example, the pre grinding closedloop system composed of roller press or external circulation vertical mill and powder concentrator has a circulation load rate of 200% – 300%, and the specific surface area of the selected materials is 180280m 2 / kg The following table lists the main machine Cement Grinding Machine Selection: Vertical Roller